The aim of car renovation in our workshop is to restore the car to the condition in which it left the factory. Each stage of the renovation is carefully documented by our team, and the documentation is shared to the client on an ongoing basis. After the renovation is completed, the customer receives a book that documents the entire process and the car receives a special number that allows it to be found in our database. In this way, both the customer and future buyers of this car can be sure that all renovation works were carried out in accordance with the art.

The full renovation process in our service is divided into the following stages:

1. Dismantling the car and preparing the body for sandblasting/glass blasting

This stage includes dismantling all suspension components, drive unit, brakes, etc. and dismantling the entire interior of the vehicle to prepare the vehicle body and sheet metal elements for sandblasting. During this stage, we perform a preliminary verification of the condition of the parts and prepare a list of parts needed for assembly.

2. Sandblasting/Glass beading or removing old varnish

This stage includes removing all paint coatings on the body and its elements and immediately securing all steel elements with an epoxy primer, which prevents corrosion. In fact, only at this point can we determine the more precise costs of bodywork and paint renovation and thus assess the validity of the renovation.

3. Bodywork repairs

During this stage, we carry out all necessary sheet metal work, such as: replacement of covers, thresholds and floors. We make elements that are not available ourselves using devices such as: English wheels, packing and stretching machines, grooving machines or a planer and a hammer. In our work, we use the most modern devices such as brazing and inverter welding machines, but we do not avoid traditional sheet metal methods such as tinning. This stage ends with professional maintenance of the chassis and re-coating the entire car with an epoxy primer, which perfectly protects the sheet metal against corrosion, and professional maintenance of the chassis.

4. Varnishing

The most time-consuming stage, which at the same time brings a lot of satisfaction to us and the client. Our workshop has its own varnish mixer allowing both the reproduction of all original varnish colors and the production of the most modern pearl colors. In our company, we only use the highest quality R-M products, which guarantees excellent results for many years. The support of experienced R-M technicians allows us to meet even the most individual requirements of our customers.

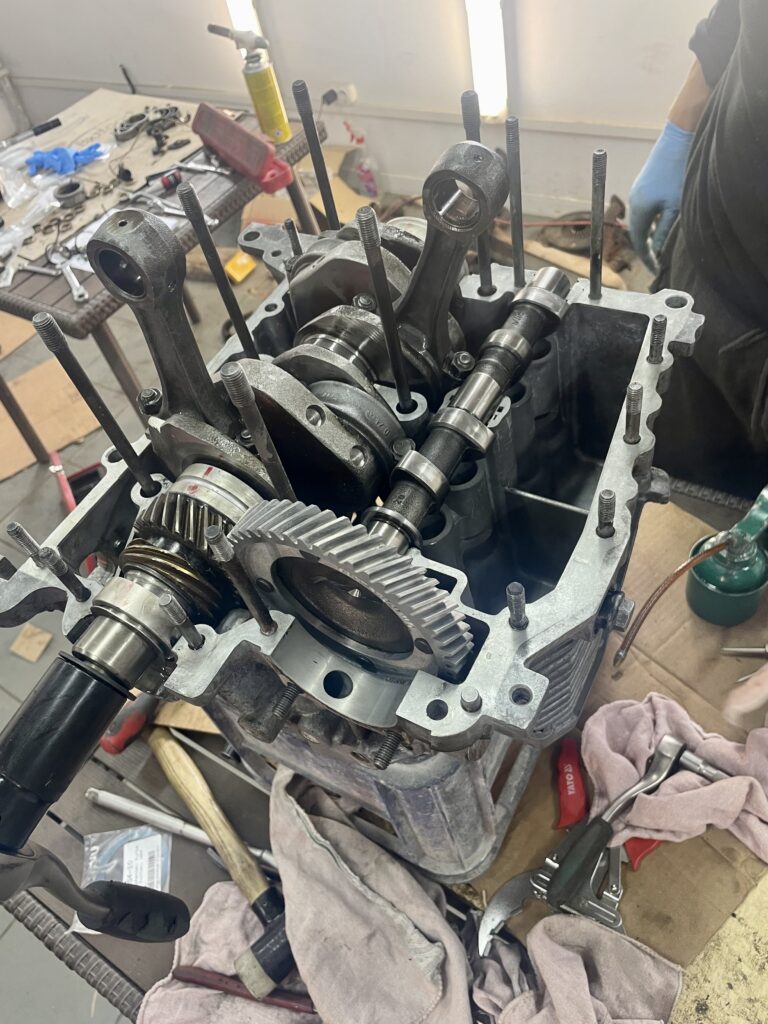

5. Mechanical overhaul

At this stage, repairs are made to all mechanical components, such as engines, gearboxes, braking systems and suspension systems. All this allows us to achieve a state in which the car after renovation drives as if it had just left the factory.

6. Upholstery

The upholstery, as well as the entire interior, can be renovated according to any customer’s idea: in accordance with the original or the craziest idea.

7. Assembling the car

When all the components are ready, they look and work like new, we can move on to the final stage, i.e. putting the whole car back together. This is a very demanding and time-consuming step due to the care and attention that must be shown when assembling all the parts to achieve an amazing end result.

8. Test drive

The most pleasant stage, during which we thoroughly inspect the car while working. This way we can be sure that the car is delivered to the customer in perfect condition.